ELECTRIC DIRTBIKE

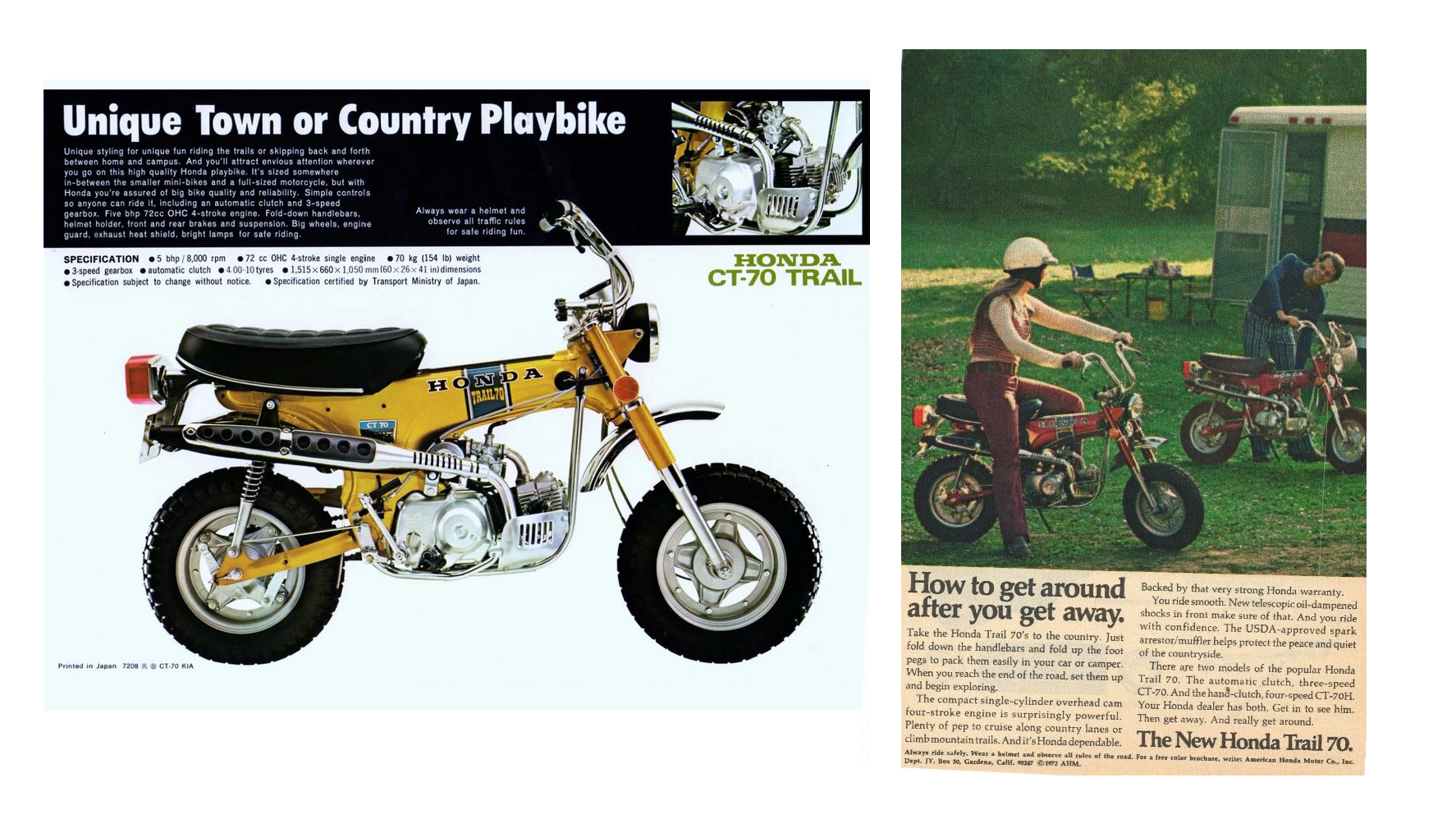

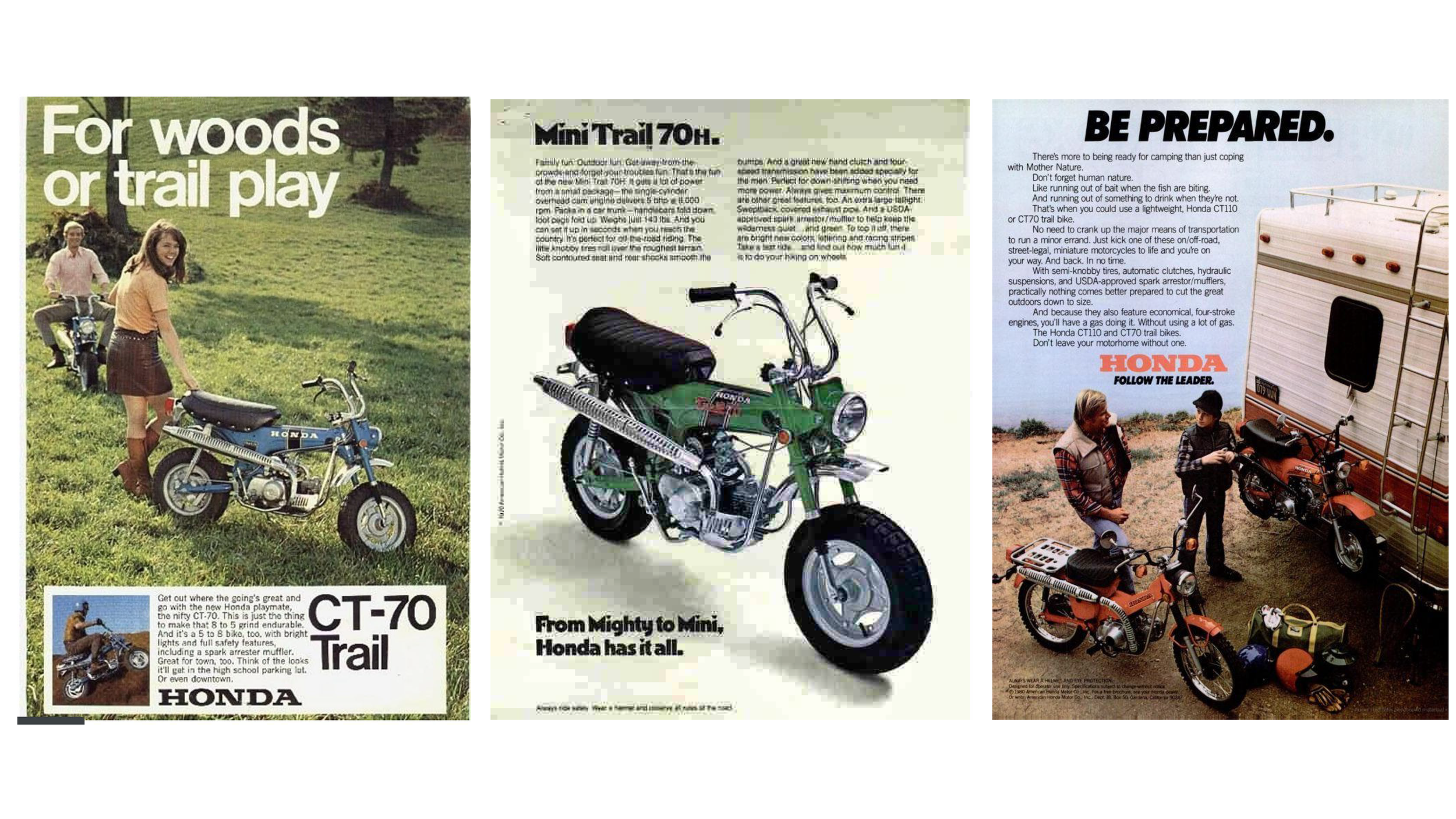

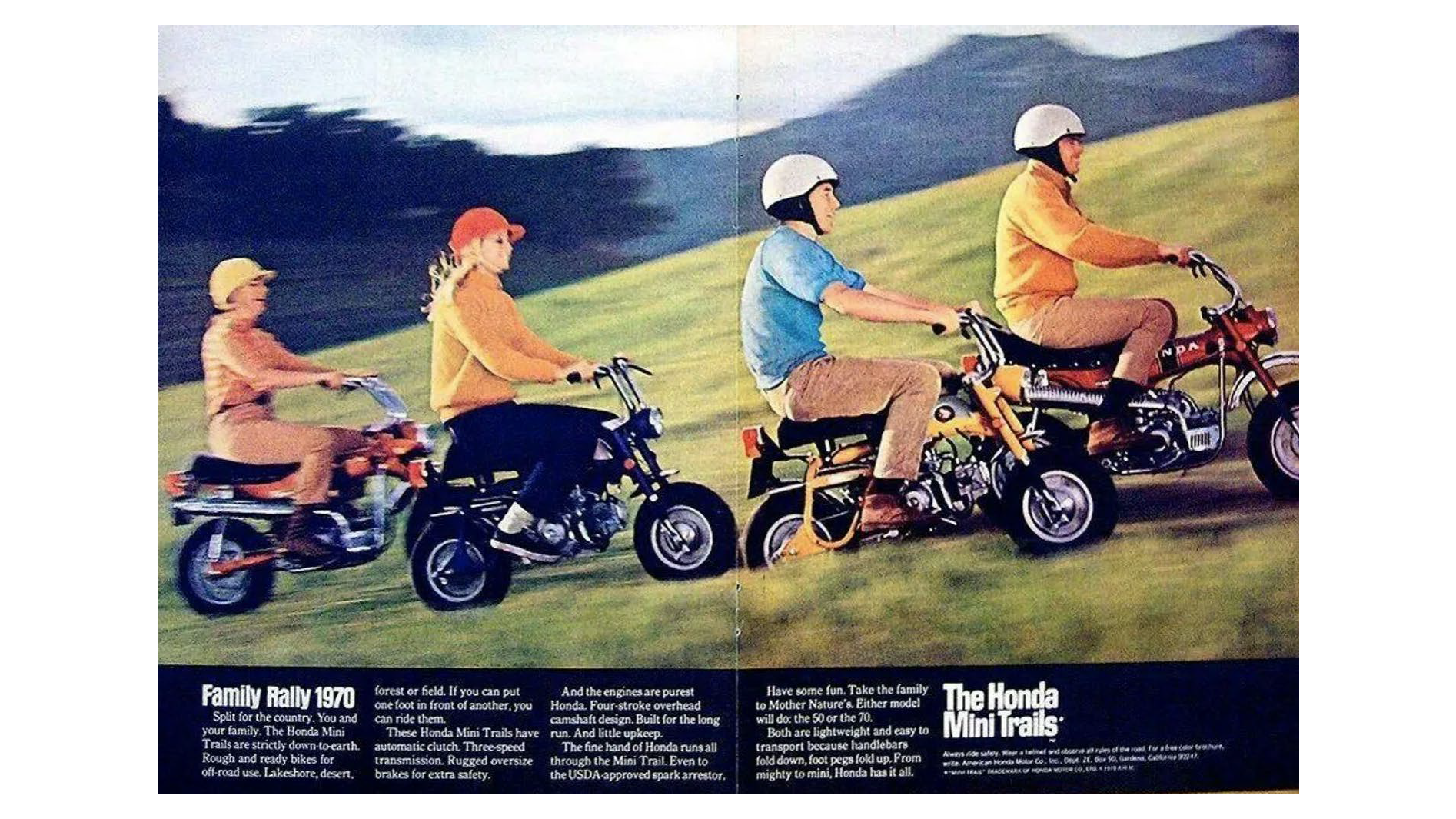

When I was 12 years old I bought my first motorcycle, a 1970 Honda CT70. It was already 27 years old and looked like a dinosaur compared to the new plastic cladded dirtbikes at the dealership, but it was mine and it sparked a lifetime of two wheeled enjoyment. So I was ecstatic when my friend reached out to me to help design an electric dirtbike.

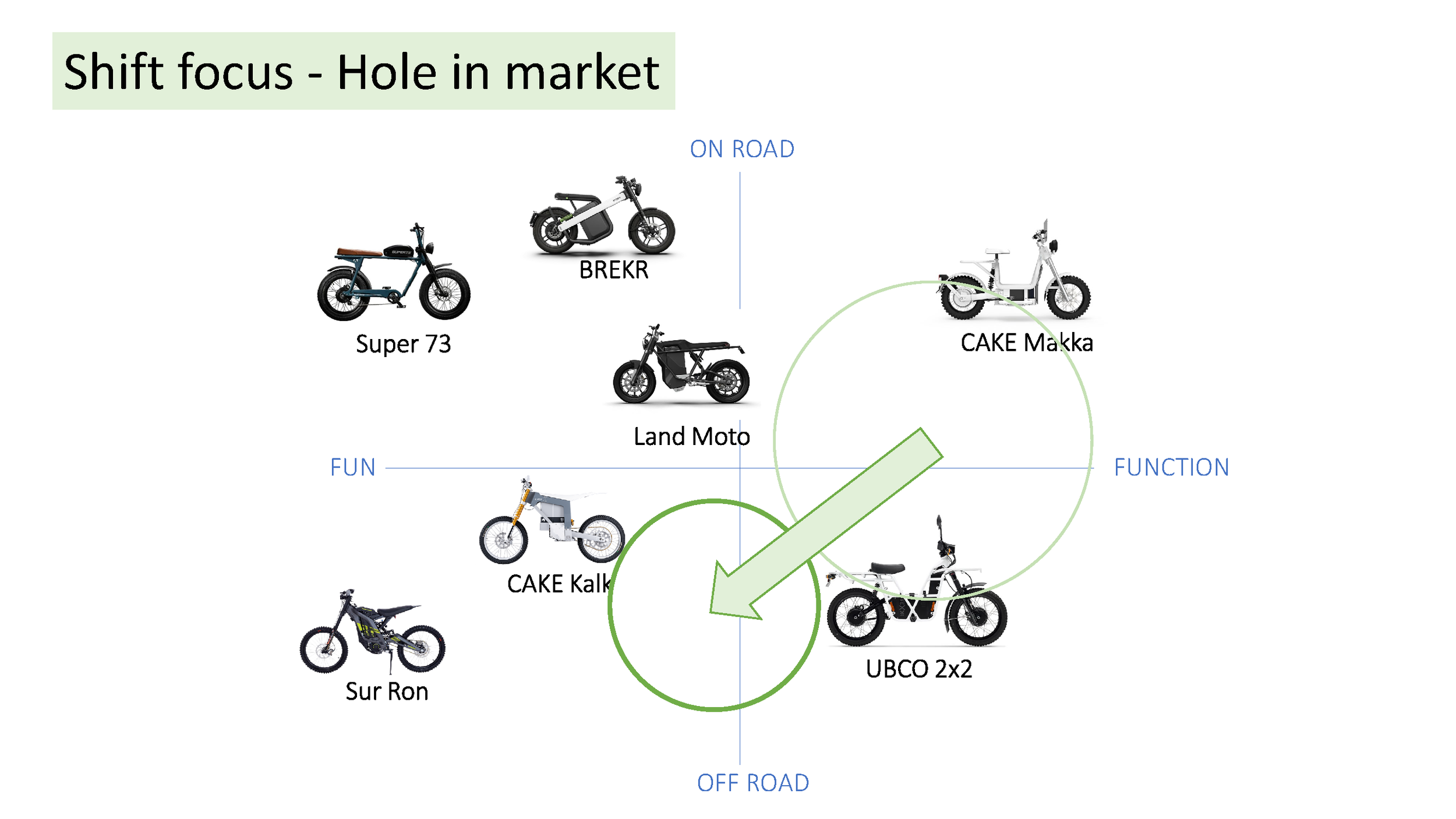

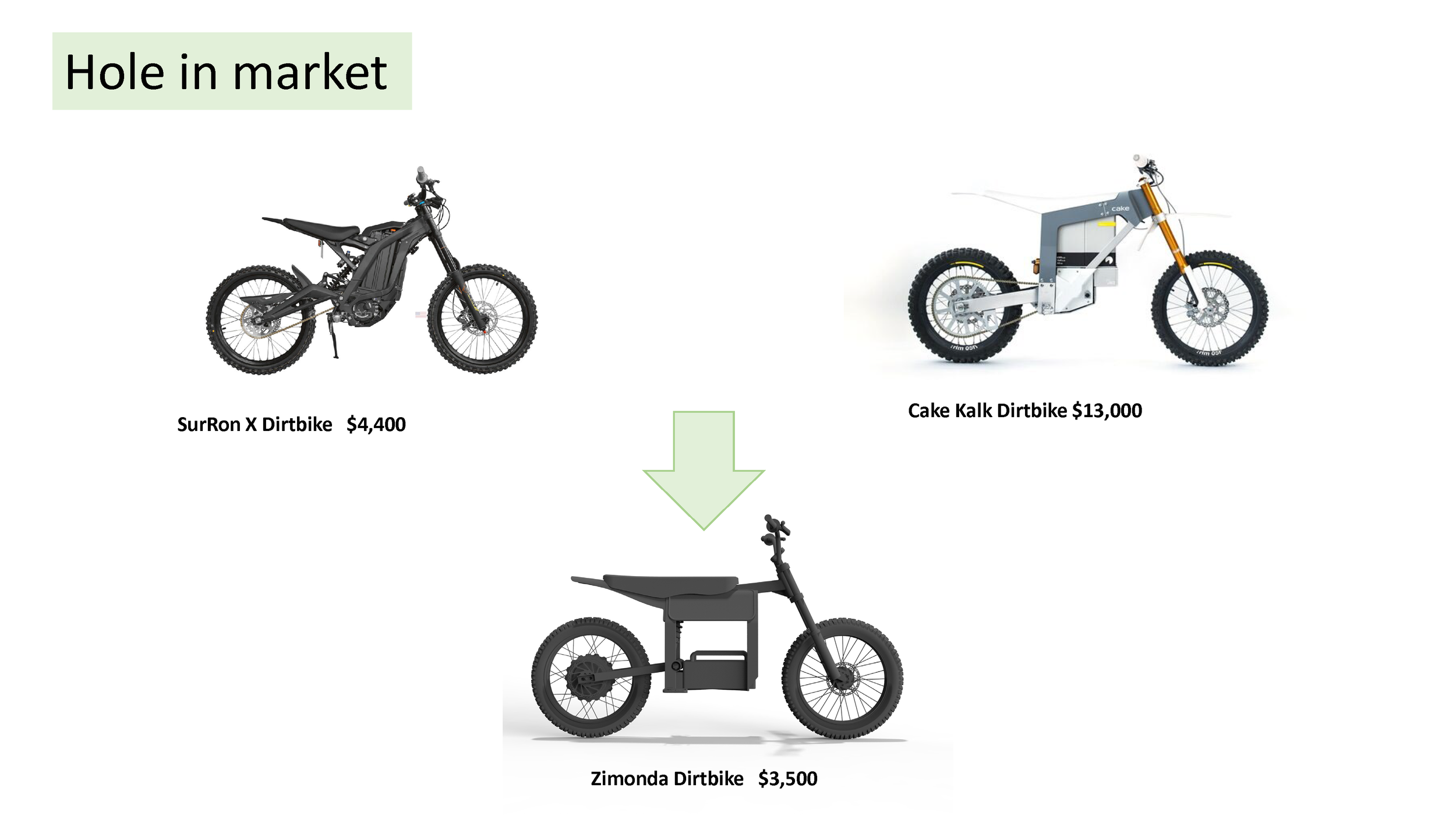

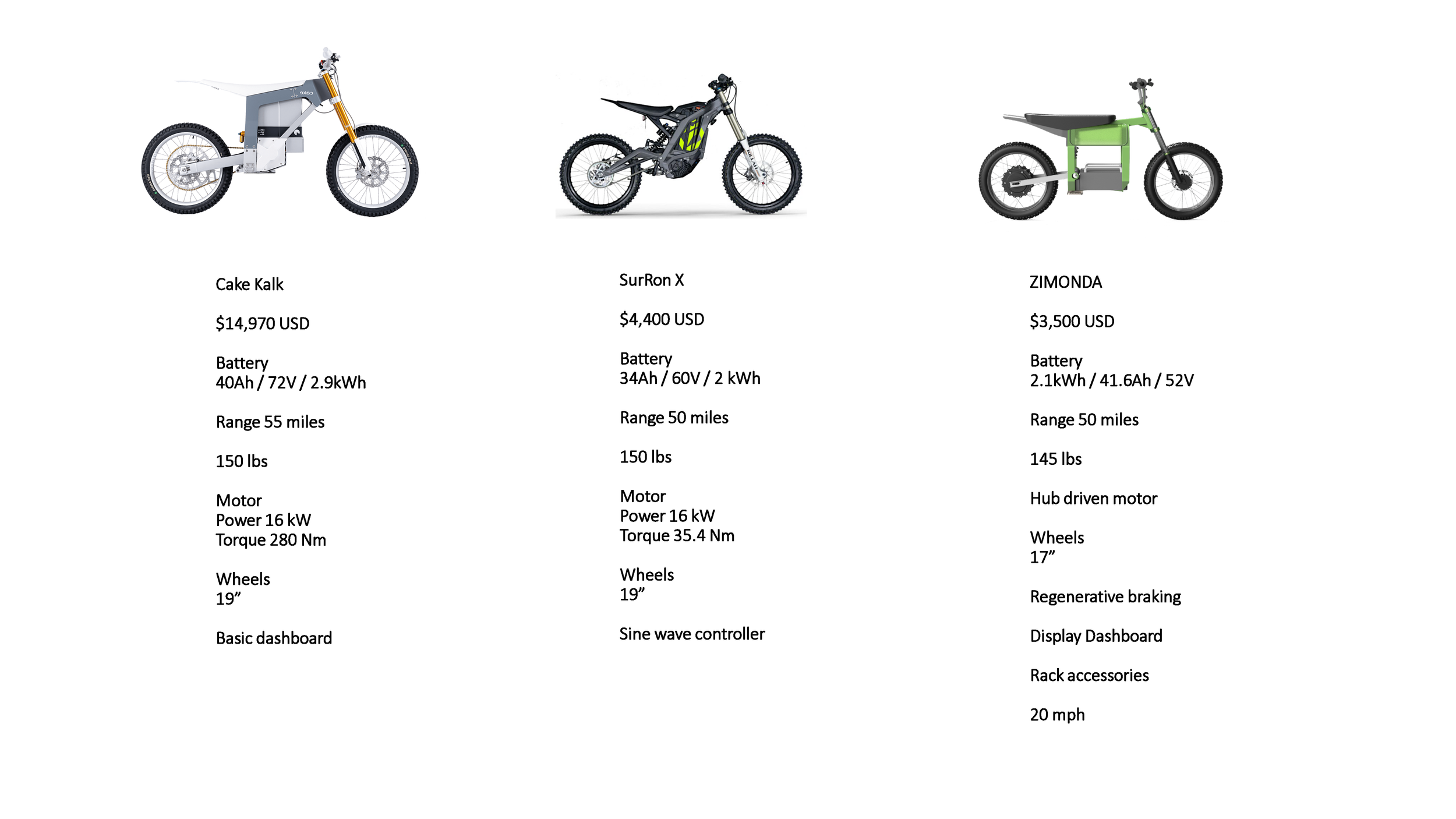

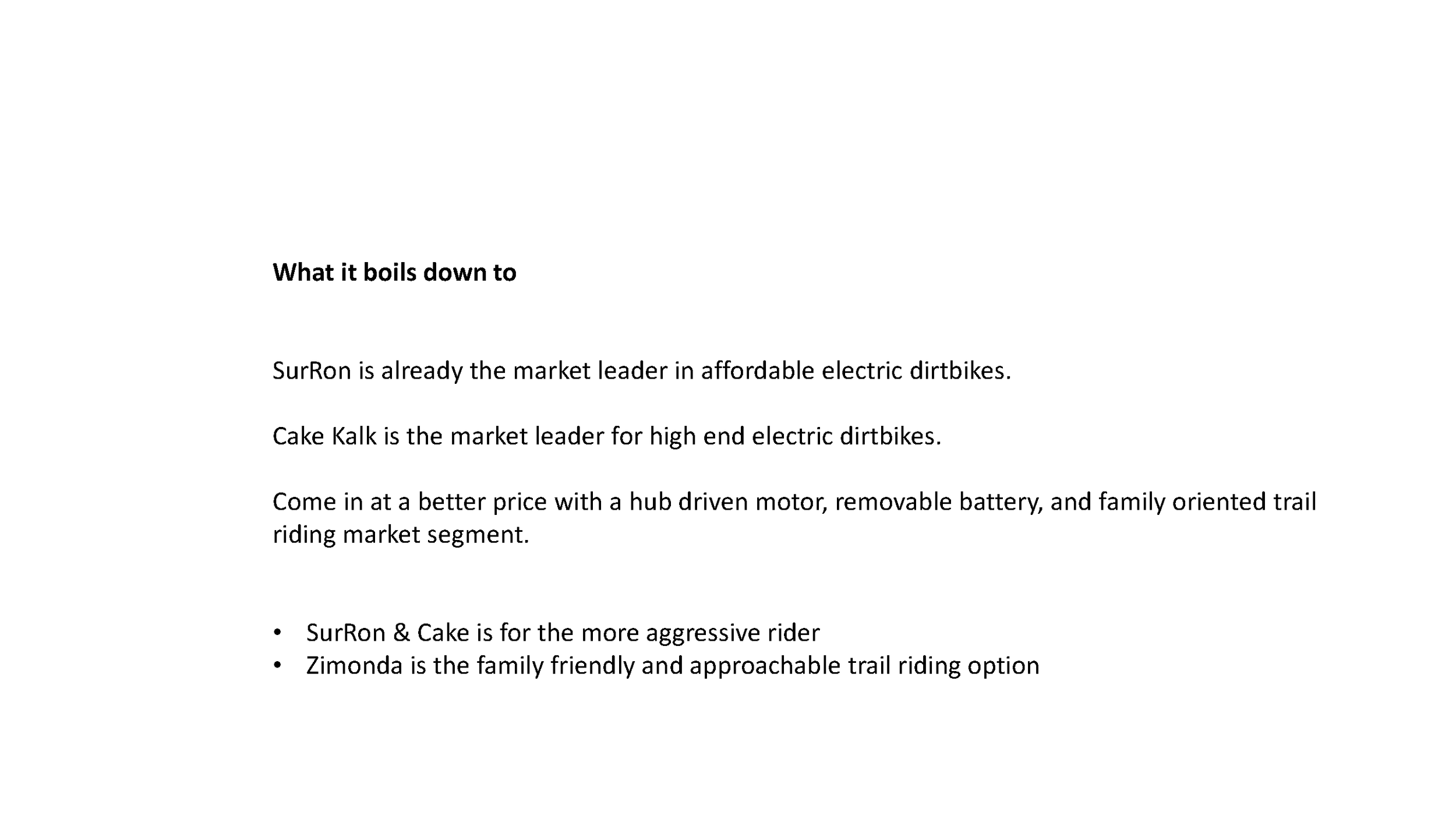

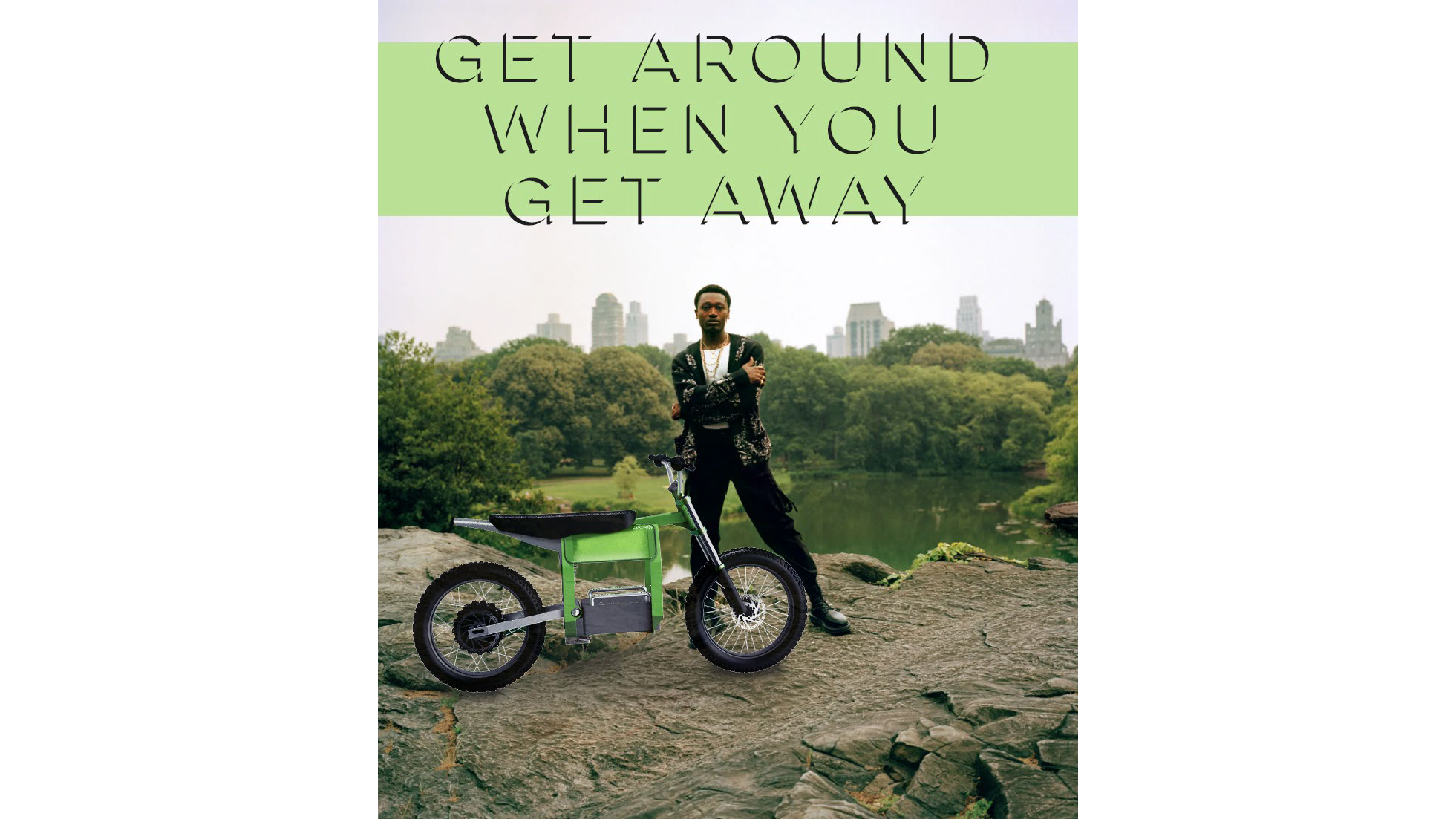

Through this project I determined a target market of an urban commuter, and looking at the current offerings, there was a need to fill the price category below the Cake Makka and above battery assisted bicycles. Through various iterations and working closely with the client, we were able to hone in on a design direction that carried the functions of a dirtbike, while leveraging the approachability of a modern moped. The hub driven rear wheel and removable battery pack allowed for simple construction and added functionality of on demand battery backup power at home or while camping.

CONCEPT Round 01

First I needed to determine a target customer, and how to break into a fast growing market of electric mopeds. Bridging the gap of entry level and premium, and focusing on the urban commuter was where I set my sights.

The first round of concepts focused on initial architectures and blush looks at aspirational forms and manufacturing methods. The client knew that they wanted a simple construction using a 1000kW rear hub driven motor and large battery. Knowing the moped would be manufactured with a lot of off the shelf components, there was a lot of focus on the frame construction and position within the electric moped market.

CONCEPT Round 02

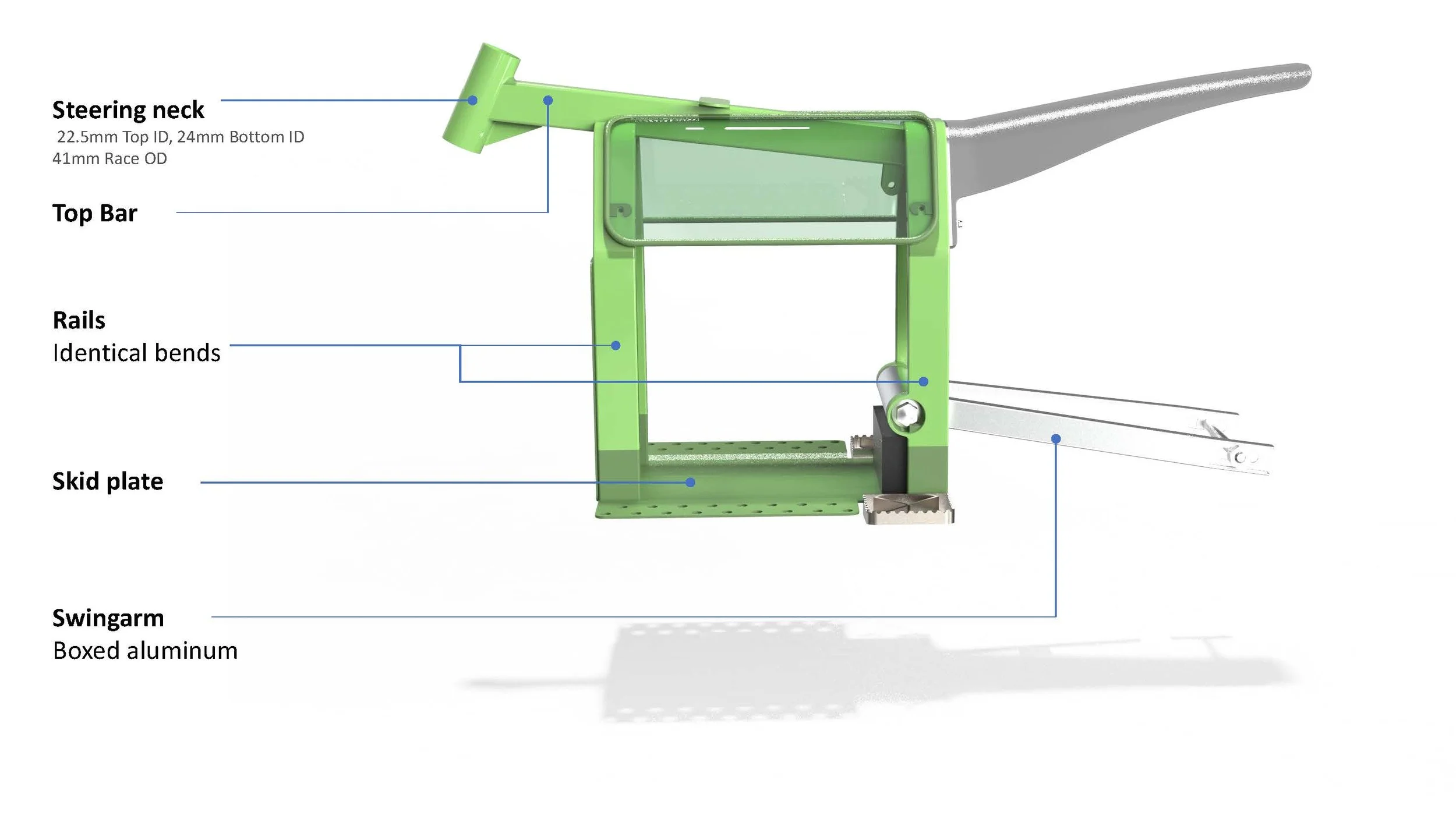

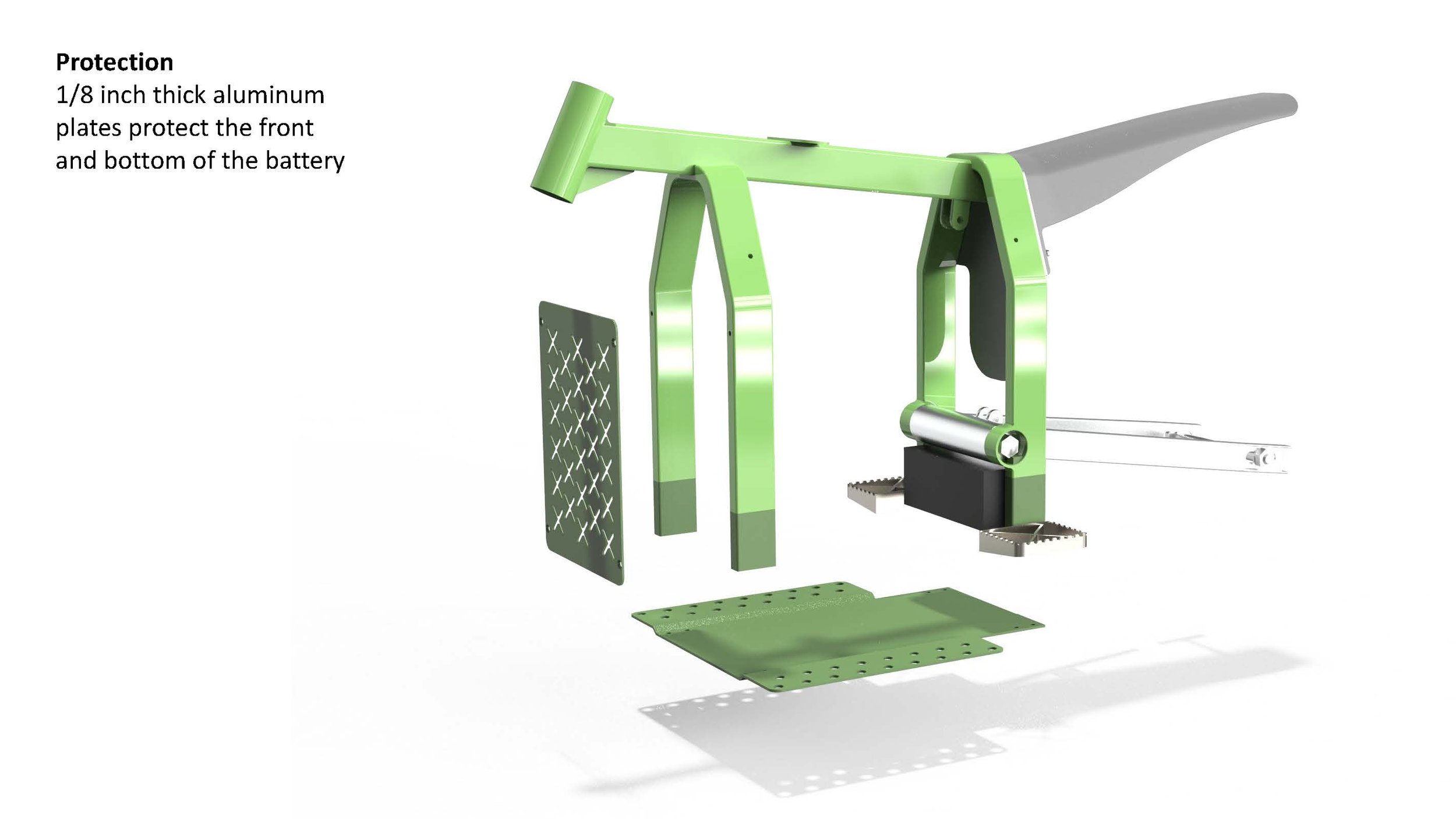

Tube, Arc, and Backbone concepts were selected by the client to move forward with. With these there was a keen focus on simple & strong frame assembly. All parts were to be designed from off the shelf tubing using common manufacturing practices. With the client being a start up, there was a lot of concern for cost while creating a unique product.

CONCEPT Round 03

Arc and Backbone are now the emerging favorites. This is where the concepts took an interesting turn. A peer who has been in this space for a few years took a look at my work and suggested I tailor the concepts for an urban commuter who wants to carry cargo. Imagine hopping on your moped carrying a 24 pack of Busch Light across town to watch the game with a buddy. One can dream.

From here I began to assemble realistic components from the client, with the 1200kW rear hub motor being the focus point. Suspension from mountain bikes, 14 inch wheels, handlebars from a pitbike.

CONCEPT ROUND 04

The client brought me back to earth. My dreams of hauling gallons of beer across town didn’t entirely match their vision for a moped. I had to regroup and focus in on why we were looking to get into this market.

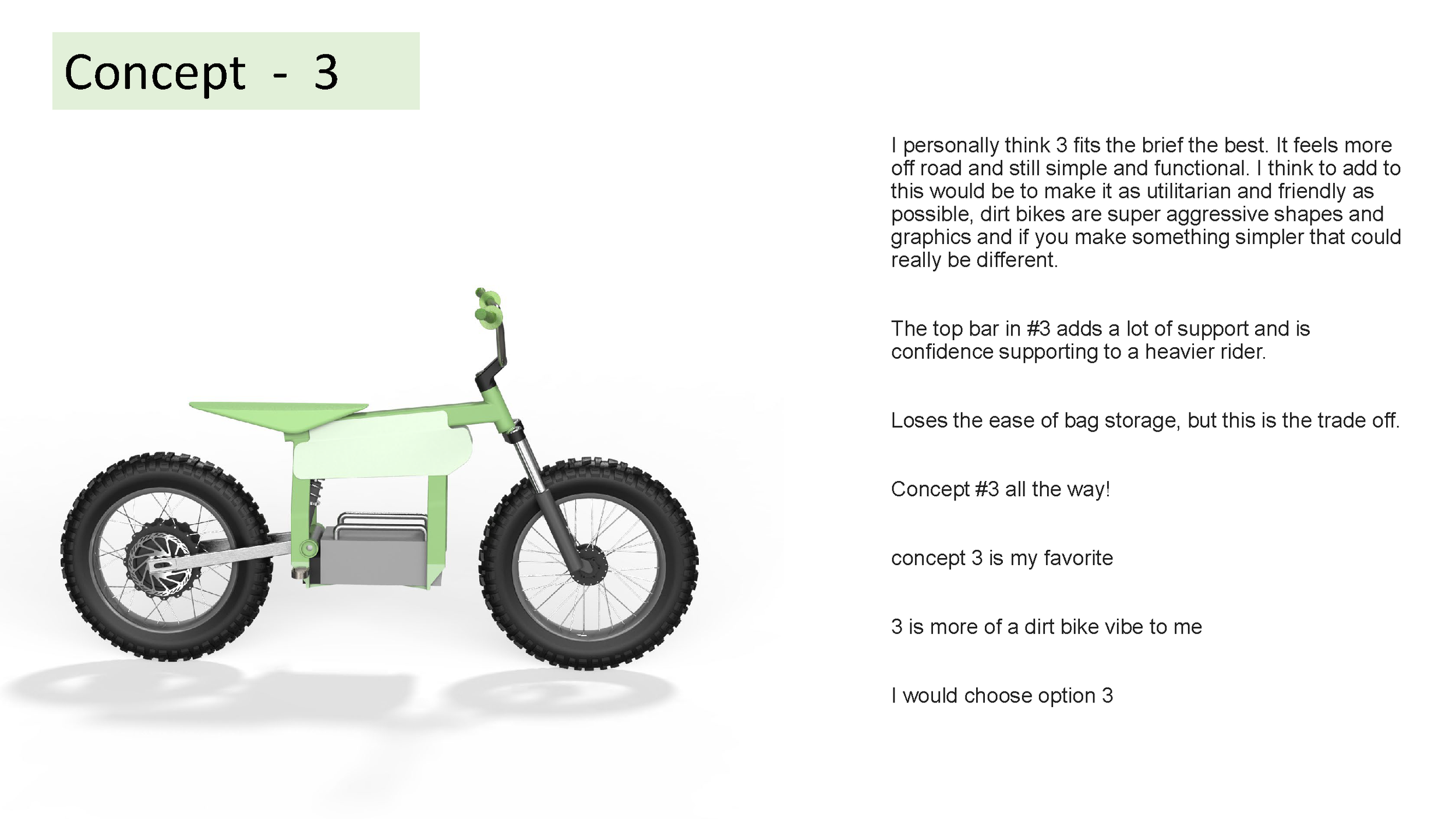

Backbone V3B was where the client wanted to take the design, and I loved the look and feel of the motorcycle. Similar enough to a dirtbike and a nice stepping stone of familiarity into the electric moped market.

FINAL DESIGN

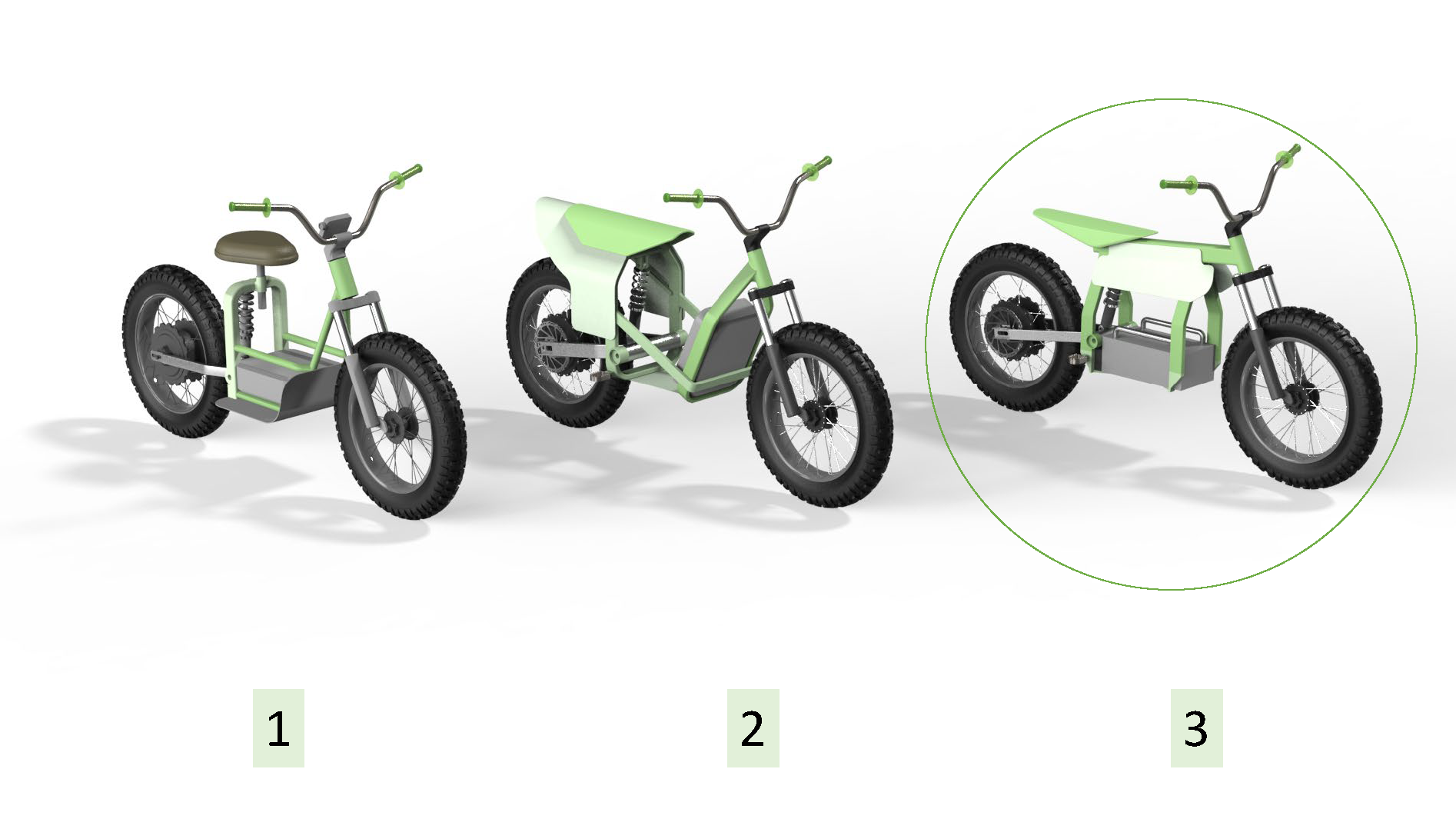

The final direction was confirmed with the client and verified with my motorcycle friendly peers.

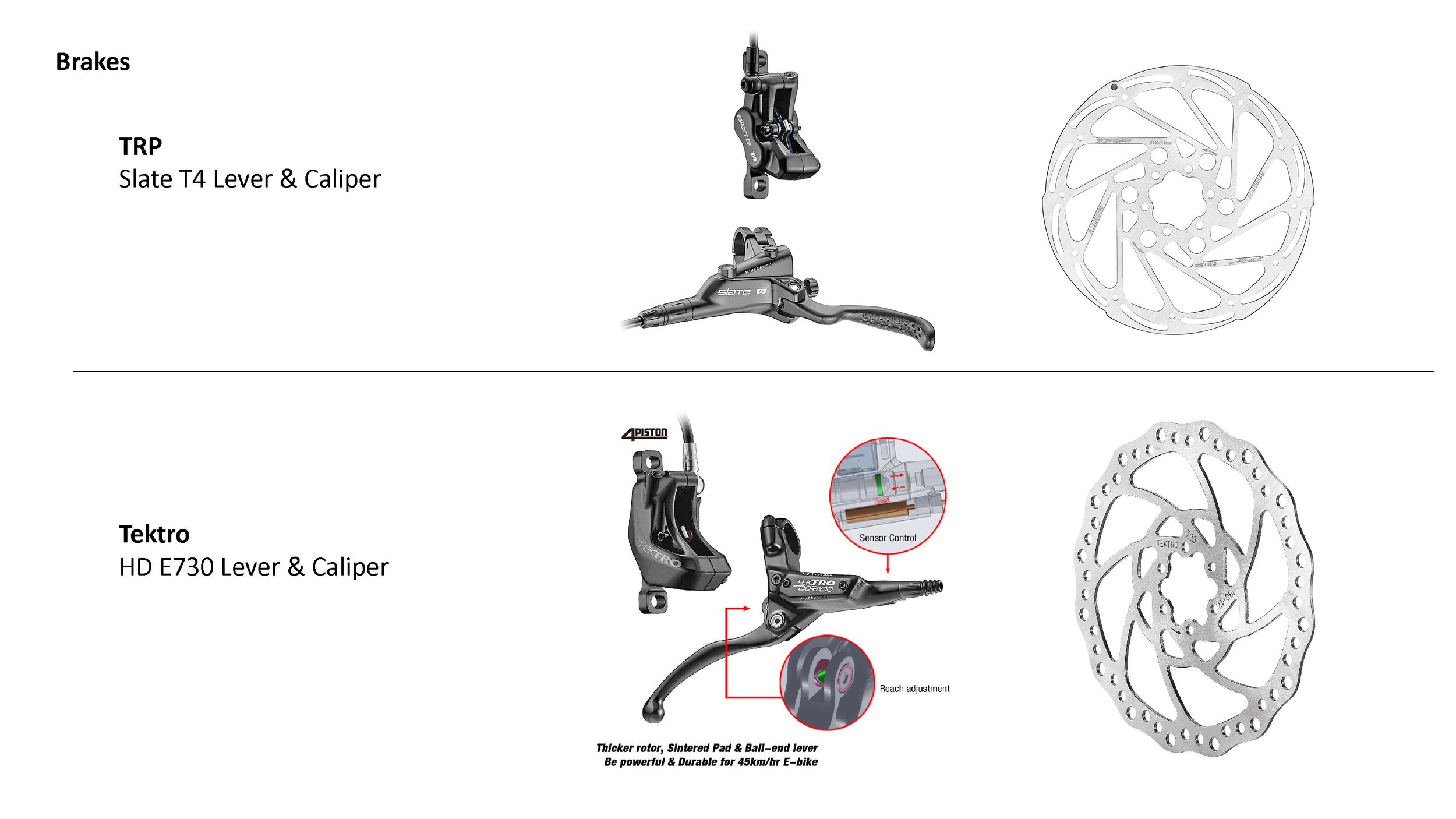

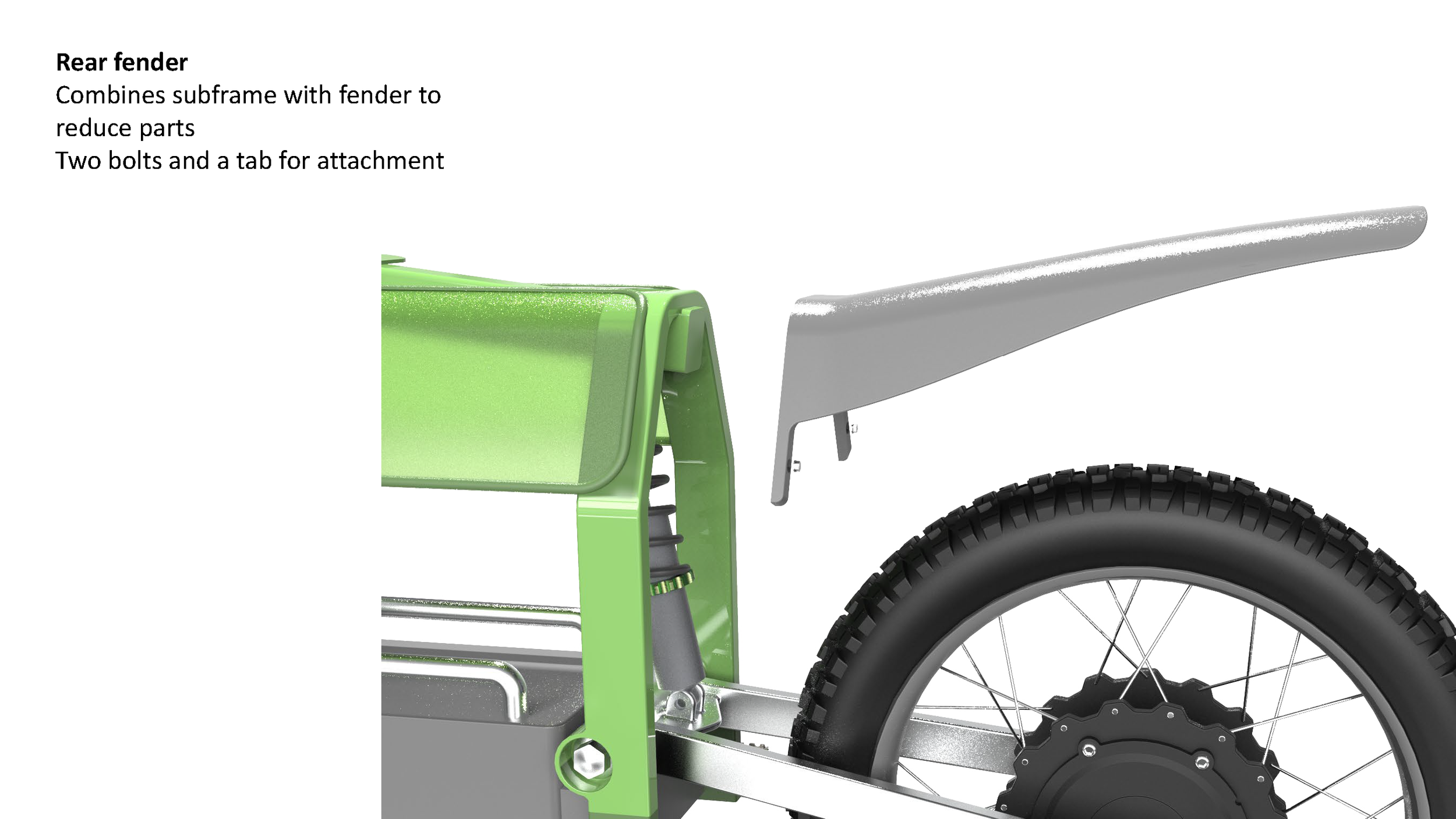

It was time to refine details, hone in on specs and begin working towards the literal nuts and bolts of the project. This is where the client decided to pause the design project and re-evaluate their investment and how committed they were to producing the concept.

CNC machined mockup I made to confirm proportions of the frame

Not all ancillary parts of the motorcycle could be sourced. The footpegs were designed to be a wide and stable platform for day to day riding. Off the shelf foot pegs were small and centered around traditional dirtbike maneuverability.

Value of the design became apparent when I began to look into accessories and how the user would get the most out of the dirtbike. A rear rack was designed from a simple construction of bent tube and laser cut and bent sheet metal. The mount points on the dirtbike were considered for other rack and pannier designs.